PHILIPS VR2022S VIDEO 2000 Reversable video cassette:

A reversible video cassette

for portable video devices is described, said cassette having two

housing halves (7, 8), mounted displaceably for changing the distance

between the winding spools. The housing halves are connected to each

other by two flat guide parts (13, 14) arranged in parallel. The two

housing halves are releasably locked by two catch hooks (17, 18)

associated with the guide parts.

A reversible video cassette

for portable video devices is described, said cassette having two

housing halves (7, 8), mounted displaceably for changing the distance

between the winding spools. The housing halves are connected to each

other by two flat guide parts (13, 14) arranged in parallel. The two

housing halves are releasably locked by two catch hooks (17, 18)

associated with the guide parts.1. Video-Wendekassette in Form eines im wesentlichen quaderf·ormigen K·orpers mit zwei darin drehbar gelagerten Wickelspulen f·ur das Magnetband und einer an einer schmalen L·angsfl·ache vorgesehenen ·Offnung mit teilweise zur·uckgesetzter Geh·ausewand zur freiliegenden Magnetbandf·uhrung, wobei die Kassette vorzugsweise aus zwei verriegelbaren im wesentlichen geschlossenen Halbteilen besteht, die zur Ver·anderung des Wickelspulenabstandes sowie zur Vergr·osserung der freiliegenden Magnetbandl·ange verschiebbar gelagert sind, d a d u r c h g e k e n n z e i c h n e t , dass die Verbindung der verschiebbaren Kassetten

-Halbteile (7,8) durch zwei flache F·uhrungsteile (13, 14) erfolgt, die in parallel angeordneten F·uhrungsnuten (19, 20), die sich in den beiden ·ausseren schmalen L·angsfl·achen (15, 16) der Geh·ausehalbteile befinden, eingelegt sind, und die Verriegelung der beiden Halbteile durch zwei seitenversetzt den F·uhrungsteilen zugeordnete Sperrhaken (17, 18) erfolgt.

2. Video-Wendekassette nach Anspruch 1, d a d u r c h g e k e n n z e i c h n e t , dass die F·uhrungsteile (13, 14) aus schmalen bandartigen Metallstreifen bestehen.

3. Video-Wendekassette nach den Anspr·uchen 1 und 2, d a d u r c h g e k e n n z e i c h n e t , dass die F·uhrungsteile aus antimagnetischem Federstahlband bestehen.

4. Video-Wendekassette nach Anspruch 1, d a d u r c h g e k e n n z e i c h n e t , dass der aus Kunststoff einst·uckig gefertigte Sperrhaken (17, 18) aus einem Hakenteil (22), einem Lagerauge (23) und einem Verbindungssteg (24) besteht, wobei der Verbindungssteg eine Schr·agfl·ache (27) aufweist.

5. Video-Wendekassette nach den Anspr·uchen 1 und 4, d a d u r c h g e k e n n z e i c h n e t , dass der Sperrhaken mittels einer Druckfeder (25) in einer die beiden Kassetten-Geh·ausehalbteile verriegelnden Lage gehalten wird.

6. Video-Wendekassette nach einem der Anspr·uche 1 bis 5, d a d u r c h g e k e n n z e i c h n e t dass die Verriegelung der beiden Kassetten-Halbteile durch Eintauchen wenigstens eines Stiftes (9, 10) in die Kassette aufgehoben wird, wobei der Stift auf die Schr·agfl·ache (27) des Sperrhaken-Verbindungssteges (24) trifft und den Haken aus einem Sperrzahn (26) hebt.

7. Video-Wendekassette nach Anspruch 6, d a d u r c h g e k e n n z e i c h n e t , dass f·ur jeden Sperrhaken ein Stift zur Entriegelung in die Kassette eintaucht. EMI11.1

REIBUNG Die Erfindung betrifft eine

Video-Wendekassette in Form eines im wesentlichen quaderf·ormigen

K·orpers mit zwei darin drehbar gelagerten Wickelspulen f·ur das

Magnetband und einer an einer schmalen L·angsfl·ache vorgesehenen

·Offnung mit teilweise zur·uckgesetzter Geh·ausewand zur freiliegenden

Magnetbandf·uhrung, wobei die Kassette vorzugsweise aus zwei

verriegelbaren im wesentlichen geschlossenen Halbteilen besteht, die zur

Ver·anderung des Wickelspulenabstandes sowie zur Vergr·osserung der

freiliegenden Magnetbandl·ange verschiebbar gelagert sind.

REIBUNG Die Erfindung betrifft eine

Video-Wendekassette in Form eines im wesentlichen quaderf·ormigen

K·orpers mit zwei darin drehbar gelagerten Wickelspulen f·ur das

Magnetband und einer an einer schmalen L·angsfl·ache vorgesehenen

·Offnung mit teilweise zur·uckgesetzter Geh·ausewand zur freiliegenden

Magnetbandf·uhrung, wobei die Kassette vorzugsweise aus zwei

verriegelbaren im wesentlichen geschlossenen Halbteilen besteht, die zur

Ver·anderung des Wickelspulenabstandes sowie zur Vergr·osserung der

freiliegenden Magnetbandl·ange verschiebbar gelagert sind.Es sind Magnetbandkassetten bekannt, bei denen die Bandwickelspulen mit einem bestimmten Abstand nebeneinander in einem Kassettengeh·ause angeordnet und die Wickelspulen von aussen ·uber ger·ateseitig angeordnete Antriebsmittel antreibbar sind. Weiterhin sind auch Kassetten bekannt, die eine Ver·anderung des Abstandes der Band wickelspulen erm·oglichen. Derartige Kassetten finden insbesondere bei Videoger·aten Anwendung. Bei Ger·aten dieser Art werden von Seiten des Benutzers, je nach Verwendungszweck, differenzierte Anforderungen gestellt.

So wird z. B. zwischen netzabh·angigen Heimger·aten und netzunabh·angigen, also batteriebetriebenen, tragbaren Ger·aten unterschieden. Hierbei spielt insbesondere das Gewicht und die Gr·osse der unterschiedlichen Ger·ate eine erhebliche Rolle. So ist die Gr·osse des Ger·ates in erheblicher Weise von der Gr·osse der Kassette abh·angig.

Bei einem tragbaren Videoger·at, das beispielsweise die Bildaufzeichnung mit Hilfe einer Videokamera erm·oglichen soll, ist eine lange Aufnahmedauer, wie sie bei einem Heimger·at gew·unscht ist, nicht erforderlich. Dagegen spielen jedoch das Gewicht und die Gr·osse bei einem tragbaren Videoger·at eine erhebliche Rolle.

Aus den unterschiedlichen Anforderungen eines Benutzers an ein Video-Heimger·at einerseits und ein tragbares batteriebetriebenes Videoger·at andererseits ergeben sich zwangsl·aufig abweichende Kassettengr·ossen mit unterschiedlicher Spieldauer. Der naheliegende Wunsch, dass die kleinere, f·ur tragbare Videoger·ate geeignete Kassette, auch auf einem f·ur gr·ossere Kassetten eingerichtetem Heimger·at abgespielt werden soll, ist schwerlich zu realisieren.

Es ist zwar bereits eine Kassettenkonstruktion bekanntgeworden, bei der auch kleinere Kassetten in einem Video-Heimger·at f·ur gr·ossere standardisierte Kassetten abgespielt werden k·onnen, die daf·ur erforderliche Konstruktion ist jedoch recht kompliziert und damit teuer.

So werden gem·ass diesem Stand der Technik Zahnrad·ubersetzungen erforderlich, mit deren Hilfe der Bandwickelabstand ausgeglichen wird.

Ein weiteres Ausf·uhrungsbeispiel zur Anpassung einer kleineren Kassette in ein Heimger·at, das nur f·ur eine gr·ossere Kassette geeignet ist, sieht vor, dass die Wickel spulen in einer besonderen Lagereinrichtung schwenkbar gelagert sind. So k·onnen die Wickel spulen mit einem kleineren Abstand in ein kleineres Kassettengeh·ause und nach Verschwenken in ein gr·osseres Kassettengeh·ause eingesetzt werden. Eine Ausf·uhrung dieser Art ist ebenfalls aufwendig und erfordert vom Benutzer ein besonderes technisches Geschick.

Eine diese Nachteile teilweise vermeidbares Ausf·uhrungsbeispiel einer Kassette zur Ver·anderung des Wickelspulenabstandes sieht vor, die Wickel spulen in getrennten, zueinander verschiebbaren Geh·ausehalbteilen unterzubringen. Die beiden Geh·ausehalbteile werden hierbei durch einen als Hohlzylinder ausgebildeten F·uhrungsabschnitt in einer festen Bewegungsbahn gef·uhrt.

Nachteilig ist hierbei, dass die F·uhrung der beiden Geh·ausehalbteile keinerlei Anpassung der auseinander gezogenen Kassetten-Geh·ausehalbteile an die Lage des im Heimger·at ver·anderten Wickelspulenantriebs erm·oglicht.

Der Erfindung liegt die Aufgabe zugrunde, eine relativ kleine Video-Wendekassette f·ur tragbare Videoger·at zu schaffen, die mit geringem technischen Aufwand auch in einem f·ur gr·ossere standardisierte Kassetten vorgesehenem Video-Heimger·at abgespielt werden kann, wobei sich der Wickelspulenabstand in der Kassette dem Spulenantrieb im Heimger·at zwangsl·aufig anpasst.

Die L·osung dieser Aufgabe erfolgt erfindungsgem·ass durch die im kennzeichnenden Teil des Anspruchs 1 angegebenen Massnahmen.

Vorteilhafte Weiterbildungen ergeben sich aus den Unteranspr·uchen.

Die Erfindung wird nachfolgend unter Bezugnahme auf die Zeichnungsfiguren beispielsweise erl·autert. Es zeigt: Fig. 1 eine perspektivisch dargestellte Video-Wendekassette mit abgenom mener Abdeckung und verriegelten Kassetten-Halbteilen, Fig. 2 eine perspektivisch dargestellte Video-Wendekassette nach Fig. 1 mit auseinandergezogenen Kasset ten-H

albteilen, Fig. 3 eine schematische Draufsicht auf eine Video-Wendekassette mit aus einandergezogenen Kassetten-Halb teilen nach Fig.2, wobei ein Be reich der Kassetten-Halbteile mit aufgebrochener Geh·ausewand ge zeichnet ist und Fig. 4 eine vergr·osserte Darstellung eines des f·ur die Verriegelung der Kas setten-Halbteile vorgesehenen Sperr hakens.

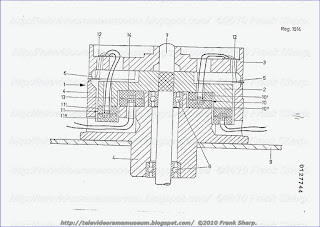

Die Figur 1 zeigt eine perspektivisch dargestellte Video Wendekassette 1 - kurz Kassette genannt - mit einer von der Kassette abgehommenen Abdeckung 2. Die Abdeckung ist f·ur den normalen Verwendungsfall der Kassette in einem tragbaren Videoger·at stets auf der Kassette aufgesetzt und sch·utzt das sonst freiliegende Magnetband 3. Beim Einlegen der Kassette in ein tragbares Videoger·at wird die Abdeckung automatisch seitlich abgeklappt, und das Magnetband ist f·ur den Zugriff von ger·ateseitig vorhandenen Ausziehstiften (nicht gezeichnet) freiliegend. Die Kassette 1 weist die Form eines im wesentlichen quaderf·ormigen K·orpers auf mit zwei darin drehbar gelagerten Magnetband-Wickelspulen 4, 5. An einer schmalen L·angsfl·ache der Kassette ist eine ·Offnung mit teilweise zur·uckgesetzter Geh·ausewand 6 zur freiliegenden Nagnetband- f·uhrung vorgesehen.

Die Kassette selbst besteht aus zwei im wesentlichen geschlossenen Halbteilen 7, 8. Die einzelnen Kassetten-Halbteile 7, 8 bestehen wiederum aus zwei fast vollst·andig geschlossenen Halbschalen, die zusammengeschraubt oder nach einer der sonst bekannten Verbindungsformen haltbar zusammengef·ugt sind. Beide Kassettenhalbteile 7, 8 sind verriegelbar und k·onnen durch Eindringen von zwei Stiften 9, 10 (strichpunktiert gezeichnet) in an der Kassette vorgesehenen F·uhrungsbohrungen 11, 12 gel·ost werden. Die Kassettenhalbteile sind sodann auf einen vorgesehenen Abstand auseinanderzuziehen.

In der Figur 2 ist die Kassette im auseinandergezogenen Zustand gezeichnet. Die Verbindung der beiden verschiebbaren Kassetten-Halbteile 7, 8 erfolgt ·uber zwei flache F·uhrungsteile 13, 14. Die F·uhrungsteile sind parallel und in geringem Abstand zu den ·ausseren schmalen L·angsfl·achen 15, 16 der Kassetten-Halbteile angeordnet. Die Verriegelung der Kassettenhalbteile erfolgt im geschlossenen Zustand der Kassette ·uber die den F·uhrungsseiten zugeordneten Sperrhaken 17, 18. Die beiden F·uhrungsbohrungen 11, 12 zur Entriegelung der Sperrhaken 17, 18 liegen im Teilungsbereich der beiden Kassetten-Halbteile 7, 8 und bestehen somit aus den vier Bohrungsh·alften 11', 11" und 12', 12''.

Aus der Figur 3 sind weitere Einzelheiten ·uber die Ausgestaltung der Sperrhaken und der Lagerung der F·uhrungsteile 13, 14 in den Kassetten-Halbteilen 7, 8 zu erkennen. Die F·uhrungsteile 13, 14 sind in F·uhrungsnuten 19, 20, die sich im Inneren der Kassetten-Halbteile befinden, gelagert. Um sicherzustellen, dass sich die Kassetten Halbteile 7, 8 nicht nur in Haupterstreckungsrichtung (s. waagerechte Pfeilangabe) der Kassette 1 gegeneinander verschieben lassen, sondern auch in begrenzter Weise senkrecht hierzu (s. senkrechte Pfeilangabe) ausweichen k·onnen, sind die F·uhrungsteile 13, 14 aus schmalem Federbandstahl gefertigt.

Die Bandwickelspulen 4, 5 in der ausgezogenen Kassette k·onnen sich somit der Lage der im Heimger·at befindlichen und gegen·uber dem tragbaren Videoger·at unterschiedlichen Antriebselementen voll anpassen. Zur Begrenzung der Auszugsl·ange der Kassette weisen die F·uhrungsteile 13, 14 Begrenzungsnasen 21 auf.

Die Figur 4 zeigt einen vergr·ossert gezeichneten Ausschnitt des Sperrhakens aus einem Kassetten-Halbteil.

Der Sperrhaken 18 besteht aus einem Hakenteil 22, einem Lagerauge 23 und einem Verbindungssteg 24. Eine Druckfeder 25, die auf dem Verbindungssteg des Sperrhakens aufgesetzt ist und sich im Geh·ause des Kassetten-Halbteils abst·utzt, sorgt f·ur den n·otigen Verriegelungsdruck bei zusammengeschobenen Kassetten-Halbteilen. Im verriegelten Zustand beider Halbteile 7, 8 liegt das Sperr haken-Hakenteil 22 des einen Halbteils in einertrSperr- zahn 26 des anderen Halbteils. ·Uber eine Schr·agfl·ache 27, die sich am Sperrhaken-Verbindungssteg befindet, kann ·uber das Auftreffen eines in die Kassette eintauchenden Stiftes 9, 10 die Verriegelung des Sperrhakens aufgehoben werden. Das Hakenteil 22 des Sperrhakens weist in bekannter Weise eine Anlaufschr·age auf ·Uber einen Lagerstift ist der Sperrhaken 18 im Kassetten-Halbteil drehbar gelagert.

e cassette housing, and a pivoting cover for the

exposed run of tape. A single cassette cover covers the entire front of

the housing, and has a pivoting arm at each side which is journalled to

the cassette housing sidewalls such that the cover can be opened from

its closed position in either direction to two different open positions,

by pivoting toward the one or toward the other main wall of the

housing. A movable slide may also cover openings which provide access

behind the stretch of tape.

e cassette housing, and a pivoting cover for the

exposed run of tape. A single cassette cover covers the entire front of

the housing, and has a pivoting arm at each side which is journalled to

the cassette housing sidewalls such that the cover can be opened from

its closed position in either direction to two different open positions,

by pivoting toward the one or toward the other main wall of the

housing. A movable slide may also cover openings which provide access

behind the stretch of tape.  1. A magnetic tape cassette comprising

1. A magnetic tape cassette comprisinga housing, having first and second plane parallel main walls, two side walls connected to the main walls, a rear, and a front having an opening between said main walls,

two adjacent reel hubs rotatably arranged between said main walls;

a length of magnetic tape having respective ends connected to the reel hubs, a portion of said length being stretched along said front opening for cooperation with parts of a magnetic tape apparatus, and

cover means, connected to and pivotable relative to the housing about an axis parallel to said main walls and the cassette front, between a closed position and an open position,

wherein said cover means comprises a single cassette cover arranged to substantially cover the entire front of the housing when in the closed position, and connecting means for pivotally connecting said cover to the housing for movement from the closed position to a first open position by pivoting in a first direction toward the first main wall, and to a second, different open position by pivoting in a second direction toward the second main wall.

2. A cassette as claimed in claim 1, wherein

said cover comprises two pivoting arms having free ends, said arms extending along respective side walls of the cassette housing toward the housing rear when in the closed position, and

said connecting means includes pivotal bearing means disposed midway between said main walls near said free ends, for connecting the cover to said side walls such that the cover is pivotable about a single axis in both directions.

3. A cassette as claimed in claim 1, further comprising resilient means for loading said cassette cover relative to other parts of the cassette, for holding the cover in a stable balanced position in its first and in its second open position for any orientation of the cassette relative to the direction of the force of gravity.

4. A cassette as claimed in claim 1, wherein

said cover comprises two pivoting arms having free ends, said arms extending along respective side walls of the cassette housing toward the housing rear when in the closed position,

said connecting means includes pivotal bearing means disposed midway between said main walls near said free ends, for connecting the cover to said side walls, and

the pivotal bearing means comprises first pivotal bearing means for pivoting the cover in the first direction about a first pivotal axis, and second pivotal bearing means for pivoting the cover in the second direction about a second pivot axis, spaced from the first axis, the first pivotal bearing means and axis being disposed nearer the first main wall, and the second pivotal bearing means and axis being disposed nearer the second main wall.

5. A cassette as claimed in claim 4, wherein

said first pivotal bearing means includes respective first bearing journals disposed on the respective pivoting arms of the cassette cover, the second pivotable bearing means includes second bearing journals disposed on the respective pivoting arms, and the cassette housing includes stops for engaging the second bearing journals to limit the pivotable movement of the cover in its first pivoting direction, and stops to engage the first bearing journals to limit the pivotable movement of the cover in its second pivoting direction.

6. A cassette as claimed in claim 4, wherein

the first pivotable bearing means comprise first bearing journals and parts of the cassette which define first bearing recesses for receiving the first bearing journals, and

the second pivotable bearing means comprises second bearing journals and parts of the cassette which define second bearing recesses for receiving the second bearing journals,

each of said bearing recesses having an opening at its circumference to allow movement of the first bearing journals out of the first bearing recesses when the cover is pivoted about the second pivoting axis, and to allow movement of the second bearing journals out of the second bearing recesses when the cover is pivoted about the first pivoting axis.

7. A cassette as claimed in claim 4, wherein

the bearing journals are disposed on the pivoting arms of the cover,

the housing side walls include arcuate first guide slots, which each terminate in the respective openings in the circumference of the first bearing recesses, for guiding the first bearing journals with play when the cassette cover is pivoted in its second pivoting direction; and second guide slots, which each terminate in the respective openings in the circumference of the second bearing recesses, for guiding the second bearing journals with play when the cassette cover is pivoted in its first pivoting direction,

each of said guide slots having an end remote from the associated bearing recess terminating at a portion of the housing side wall, said side wall portion being one of said stops for limiting pivotable movement of the cover.

8. A cassette as claimed in claim 6, wherein

parts of the cassette define arcuate first guide slots, which each terminate in the respective openings in the circumference of the first bearing recesses, for guiding the first bearing journals with play when the cassette cover is pivoted in its second pivoting direction, and

parts of the cassette define arcuate second guide slots, which each terminate in the respective openings in the circumference of the second bearing recesses, for guiding the second bearing journals with play when the cassette cover is pivoted in its first pivoting direction.

9. A cassette as claimed in claim 8, wherein

the bearing recesses have an at least partly circular cross-section with a diameter equal to the maximum transverse dimension of the associated bearing journal plus the play,

the bearing journals have an elongate shape, with a width dimension which is smaller than the length dimension, and

the arcuate guide slots have a width dimension which is adapted to the width dimension of the associated bearing journal and is smaller than the diameter of the associated bearing recess so as to prevent movements of the cassette cover other than in the first or the second pivoting direction in every position of the cassette cover.

10. A cassette as claimed in claim 9, wherein

said bearing journals are disposed on the pivoting arms of the cover, and the guide slots are located in the housing side walls, and

each side wall of the housing further includes mounting slots extending in the direction of the bearing recesses and intersecting the guide slots at intersections, for mounting the bearing journals in the bearing recesses, said mounting slots each having an open entry side to allow unimpeded entry of the bearing journal into the mounting slot and having a bottom with a profile which extends between a first level at which there is play between the cassette cover and the cassette housing, and a second level at which the cassette cover has an interference fit between the respective bearing journals and the bottoms of the mounting slots.

11. A cassette as claimed in claim 1, each main wall having at least one cut-out which extends to the cassette front, to permit passage of an element of a cassette apparatus behind the stretched portion of the tape and withdrawal of the tape from the housing at the front,

wherein the cassette further comprises first and second slide plates disposed respectively near the first and second main walls, and means for mounting said slide plates to the housing for movement between a closing position nearer the front of the cassette and a retracted position nearer the rear of the cassette, in the closing position each slide plate at least partly closing the respective cut-out openings in the respective main wall, in the retracted position the slide plate being clear of said respective cut-out openings.

12. A cassette as claimed in claim 11, wherein

said two slide plates are parts of a single slide member which is bodily movable between a retracted position and a closing position, said member further including two side walls which extend along the side walls of the cassette housing and which interconnect the slide plates.

13. A cassette as claimed in claim 12, wherein

said slide member consists of a unitary plastic molding.

14. A cassette as claimed in claim 12, wherein

the slide member consists of two identical parts each having snap-connection means for interconnecting said identical parts through a snap connection, each of said identical parts being a unitary plastic molding.

15. A cassette as claimed in claim 12, wherein

said cover comprises two pivoting arms having free ends, said arms being disposed on the outside of the cassette housing, and extending along respective side walls of the cassette housing toward the housing rear when in the closed position, the slide member being arranged such that in the closed position of the cassette cover the slide member side walls cover the pivoting arms.

16. A cassette as claimed in claim 12, comprising resilient means for urging the cassette cover and the slide member toward each other, for holding the cassette cover in a stable balanced position under the influence of the resilient urging in its first and in its second open positions for any orientation of the magnetic tape cassette relative to the direction of the force of gravity.

17. A cassette as claimed in claim 12, wherein

each slide member side wall includes a portion prolonged to the rear of the cassette housing, so arranged that in the closing position of the slide member each side wall of the said member extends beyond the location of rear edges of the side plates when the slide member is in the more retracted position.

18. A cassette as claimed in claim 12, wherein

said slide member and said housing include cooperating stop means for preventing a slide member, mounted on the housing, from sliding off the housing in the absence of the cassette cover.

19. A cassette as claimed in claim 18, wherein

said cooperating stop means are arranged so that when the slide member is in its closing position a portion of said slide member abuts a portion of the cassette housing, and wherein said cassette includes resilient means which act both on the cassette housing and the slide member for urging the slide member toward the closing position, whereby in the closing position said stop means transmits the resilient load from the slide member to the cassette housing.

20. A cassette as claimed in claim 12, wherein

said slide member and said cassette cover include cooperating parts for causing the cassette cover to pivot toward the closed position from either one of the two open positions.

21. A cassette as claimed in claim 20, wherein

the slide member and the cassette cover include cooperating latching means for preventing the cassette cover from moving to a open position when the slide member is in the closing position.

22. A cassette as claimed in claim 21, wherein

each of the side walls of the slide member has an edge remote from the rear of the cassette housing arranged to be clear of the cassette cover, at least at locations disposed near the main walls of the housing, for engagement by an element of a cassette holder when the cassette is inserted into a cassette apparatus, so as to move the slide member to its more retracted position.

23. A cassette as claimed in claim 22, wherein

each of said edges of the slide member side walls includes a notch located midway between the main walls of the housing, and the cassette cover includes lateral projections for engaging the respective notch when the cassette cover is closed.

24. A cassette as claimed in claim 12 wherein,

at the location of the side walls of the slide member when this member is in its more retracted position, each of the side walls of the housing has a curved profile having a radius of curvature substantially equal to the distance between the two housing side walls, so arranged that the slide member may undergo at least limited twisting relative to the cassette housing whereby one side wall of the slide member becomes disposed nearer the rear of the cassette housing than the other slide member side wall, without jamming of the slide member on the housing.

25. A cassette as claimed in claim 12, comprising resilient means for urging the slide plates toward their closing positions, said resilient means acting both on the cassette housing and on the slide plates.

26. A cassette as claimed in claim 25, wherein

said two slide plates are parts of a single slide member which is bodily movable between a retracted position and a closing position, said member further including two side walls which extend along the side walls of the cassette housing and which interconnect the slide plates,

said slide member further including a connecting member halfway between the member side walls, behind the stretched tape portion, and

said resilient means for loading the slide member toward the closing position comprises a pressure spring bearing against the connecting member and the cassette housing.

27. A cassette as claimed in claim 26, wherein said slide member and the connecting member together consist of a unitary plastic molding.

28. A cassette as claimed in claim 26, wherein

the slide member consists of two identical parts each have snap-connection means for interconnecting said identical parts through a snap connection, each of said identical parts being a unitary plastic molding, and

said connecting member is formed by identical parts of said two identical parts.

Description:

BACKGROUND OF THE INVENTION

1. Field of the Invention

The invention relates to a magnetic tape cassette which is adapted to cooperate, in a first position and in a reversed second position, with parts of a cassette recording and/or playback apparatus (hereinafter referred to as a cassette apparatus); and more particularly to a cassette having first and second adjacently disposed reel hubs, which are rotatable about parallel spaced first and second axes of rotation in a cassette housing; a length of magnetic tape having a first end connected to the first reel hub and having a second end connected to the second reel hub, so as to enable it to be wound from the first reel hub to a reel on the second reel hub and back from the second reel hub to a reel on a first reel hub, and having a stretched tape portion along a front opening of the cassette housing for cooperation with parts of a cassette apparatus; and cover means connected to the cassette housing and pivotable relative thereto about a pivoting axis which is parallel to the main walls between a closed position and an open position. In the closed position, the cover extends along the front of the cassette housing, to at least partly cover the stretched portion of the magnetic tape and thus protect the magnetic tape against inadvertent damaging when the magnetic tape cassette is not placed on a cassette apparatus. The open position, when the magnetic tape cassette is placed on a cassette apparatus, allows parts of the cassette apparatus to cooperate with the stretched portion of the magnetic tape.

Magnetic tape cassettes in a variety of versions have gained a high degree of popularity in various fields of application. This may be attributed to the high vulnerability of the magnetic tape medium when not accommodated in a cassette. The magnetic tapes commonly used in magnetic tape equipment for the consumer market and also for many semiprofessional and professional uses have a thickness dimension which is very small in comparison with the width dimension. The thickness dimensions generally range between 15 and 40 um, while the width for the more customary magnetic tapes varies roughly between 12 and 25 mm. The magnetic tapes consist of a plastic foil which on one side is provided with a finely dispersed magnetizable material, and has an extremely high degree of flexibility. The magnetic tape cassette affords protection against damaging of the delicate and vulnerable magnetic tape, so that the ease of handling the magnetic tape medium is substantially improved.

For many simple applications it suffices if the front of the cassette is at least partly closed and is provided with openings for the passage into the cassette of parts of a cassette apparatus, such as a recording/playback head, an erase head and a pressure roller. Such a cassette is for example the so-called Compact Cassette, also referred to as the Philips cassette, which is generally used for audio purposes. With this cassette the magnetic tape need never be removed from the housing, so that the front may be partly closed and thus affords adequate protection of the magnetic tape against inadvertent touching. While dust can reach the magnetic tape through the openings, this seldom presents a problem in that tape application.

Still other known cassettes are intended for use with a cassette apparatus which includes a device for partly withdrawing the magnetic tape from the cassette housing and bringing the portion of the magnetic tape thus removed from the cassette housing into contact with the magnetic heads. For audio applications this enables a better guidance of the magnetic tape during its transport from the one reel to the other along the magnetic heads to be obtained, so that higher quality standards in respect of signal recording and reproduction can be achieved than with the previously mentioned Compact Cassette, in which the lace-up is determined by components of the cassette housing.

In known magnetic video tape equipment for home-entertainment use, which to date are always equipped with rotary magnetic heads which write obliquely oriented closely spaced tracks on the magnetic tape, the magnetic tape should also be withdrawn from the cassette housing. The front of the cassette housing must then be free of wall portions which could interfere with the withdrawal of the magnetic tape from the cassette housing. As a result of the absence of wall portions at the front the likelihood of the magnetic tape being touched inadvertently increases. This likelihood is further increased because the cassette apparatus customarily includes a device for withdrawing the magnetic tape from the cassette housing. Such a device enters the cassette housing through the main walls behind the magnetic tape and should engage the back side of the magnetic tape during withdrawal. Therefore, cut-outs which extend to the front are necessary in the main walls of the cassette. These cut-outs expose the edges of the magnetic tape, which exposure greatly increases the likelihood of the magnetic tape being damaged.

Another aspect of cassette design is that, when magnetic tape cassettes are used on equipment which enables higher quality audio recording and reproduction or which enables video signals to be recorded and reproduced, dust should be prevented from reaching the magnetic tape as far as possible, because dust may affect the high quality of recording and reproduction.

Therefore many magnetic tape cassettes are provided with movable cover means in order to protect the stretched portion of the magnetic tape which extends along the fro

nt of the magnetic tape cassette when the magnetic tape cassette is not located on a cassette apparatus.

nt of the magnetic tape cassette when the magnetic tape cassette is not located on a cassette apparatus.2. Description of the Prior Art

Magnetic tape cassettes which are suitable for use on a cassette apparatus in a first position only and which are consequently not suitable for cooperating with the apparatus in a reversed or "flipped over" second position, so-called non-reversible cassettes, present fewer problems in respect of the protection of the magnetic tape, because only one of the two main walls need be provided with cut-outs for withdrawal of the magnetic tape from the cassette. Such a cassette is for example known from U.S. Pat. No. 3,900,172. A cassette cover closes the front of the cassette housing if the cassette is removed from a cassette apparatus. On its side which faces the rear of the cassette the cassette cover has an additional ridge which covers the back side of the magnetic tape when the cassette cover is closed. Although one of the main walls of the cassette has a comparatively large opening this still provides satisfactory protection of the magnetic tape. However, dust can still rather easily reach the magnetic tape, and the tape can readily be damaged by the ridge if the stretched portion of the magnetic tape in the cassette is not sufficiently taut.

In the case of reversible magnetic tape cassettes this solution cannot be adopted. If the housing of a reversible magnetic tape cassette has cut-outs in the main walls for withdrawal of the magnetic tape from the magnetic-tape cassette, the cut-outs should be formed in both main walls. From German Offenlegungsschrift No. 2,552,063, to which U.S. Pat. No. 4,021,006 corresponds, a reversible magnetic tape cassette of this type is known, having two cassette covers which partly extend along the front of the cassette housing: a first cassette cover on the side near the first main wall of the cassette housing, and a second cassette cover on the side near the second main wall of the

cassette housing. When the cassette covers are closed a part of the first cassette cover is situated in the plane of the first main wall and a part of the second cassette cover is situated in the plane of the second main wall. At the front of the magnetic tape cassette perpendicular to these parts, half-height front cover portions extend parallel to the rear of the cassette housing, and are thus perpendicular to the first-mentioned parts of the cassette covers. The first cassette cover is pivotable about a first pivoting axis disposed near the first main wall of the cassette housing and the second cassette cover is pivotable about a second pivoting axis disposed near the second main wall of the cassette housing. The two pivoting axes are parallel to each other and parallel to the main walls. The two cassette covers also have gear-segments which engage with each other. When the one cassette cover is pivoted the second cassette cover is thus pivoted simultaneously and to the same extent. Each cassette cover covers the front of the cassette housing over half its height.

cassette housing. When the cassette covers are closed a part of the first cassette cover is situated in the plane of the first main wall and a part of the second cassette cover is situated in the plane of the second main wall. At the front of the magnetic tape cassette perpendicular to these parts, half-height front cover portions extend parallel to the rear of the cassette housing, and are thus perpendicular to the first-mentioned parts of the cassette covers. The first cassette cover is pivotable about a first pivoting axis disposed near the first main wall of the cassette housing and the second cassette cover is pivotable about a second pivoting axis disposed near the second main wall of the cassette housing. The two pivoting axes are parallel to each other and parallel to the main walls. The two cassette covers also have gear-segments which engage with each other. When the one cassette cover is pivoted the second cassette cover is thus pivoted simultaneously and to the same extent. Each cassette cover covers the front of the cassette housing over half its height.When this known magnetic-tape cassette is placed on a cassette apparatus, a unit on the deck of the cassette apparatus partly opens the two cassette covers, after which the magnetic heads are brought into contact with the magnetic tape through the slot between the two cassette covers. The magnetic tape cassette has cut-outs in the main walls for bringing the magnetic tape into contact with two pressure rollers by means of two capstans on either side of the magnetic head, which capstans are situated behind the magnetic tape.

A disadvantage of this known cassette is that both in the first and in the second position of the magnetic tape cassette on a cassette apparatus the two cassette covers must be opened. One of the two cassette covers is then always pivoted into a position in which it moves toward and faces the cassette apparatus. In the cassette apparatus the magnetic tape cassette should therefore be supported in such a way that there is sufficient clearance between the main wall of the magnetic tape cassette which faces the cassette apparatus and the parts of the apparatus near that wall. Another drawback is that the opened cassette covers constitute an obstruction to the device which withdraws the magnetic tape from the cassette, unless the cassette covers are opened very far. This last alternative demands a still greater clearance. Otherwise both sides adjacent the cassette covers must have cut-outs formed which open towards the front, as in the known cassette, so that the magnetic tape is exposed at these locations. The spaced required above the cassette for the opened cassette cover is comparatively large, because the cassette cover portion which is disposed in the main wall also pivots upwards. This is a drawback because the overall height of a cassette apparatus should be minimized for obvious reasons.

Therefore, the known magnetic tape cassette is less suitable for application where the magnetic tape is to be withdrawn from the cassette housing. Moreover, unless openings are formed in the main walls of the cassette housing on both sides of the cassette covers for the passage of the tape withdrawal elements of a cassette apparatus, which means that there will be locations on both sides of the cassette covers where the magnetic tape can be touched and damaged, the two cassette covers should be pivoted into their open positions before the magnetic tape cassette is moved to an operating position over the withdrawal elements of the cassette apparatus. However, for thus swinging open the cassette covers before the magnetic tape consists is completely in its operating position, the known magnetic tape cassette is less suitable because of the actuation elements for the cassette covers which are then required. Further, the part of the cassette cover which faces the deck of the cassette apparatus and which is situated at the front of the cassette housing constitutes an obstruction for the withdrawal elements even if the cassette covers are swung open very far.

SUMMARY OF THE INVENTION

It is the object of the invention to provide a magnetic tape cassette which may be inverted or flipped over, and which provides good protection against dust or accidental touching when closed, but does not require excessive clearance between the cassette and the apparatus.

Covers

In accordance with the invention a single cassette cover substantially covers the entire front of the cassette housing; and on both sides the cassette cover is provided with pivoting arms which extend along the side walls of the cassette housing toward the rear of the cassette housing in the closed position, from its closed position the cassette cover being pivotable into either of two different open positions, one towards the first main wall of the cassette housing and the other towards the second main wall of the cassette housing.

In the cassette in accordance with the invention the entire front of the cassette housing is covered, so that if the main walls have cut-outs which extend to the front of the cassette housing, the tape is protected to some extent against inadvertent touching. As the cassette cover is movable in either of two pivoting directions, a magnetic tape cassette is obtained which on its side which faces a cassette apparatus has no obstacles which impair placing of the cassette on the cassette apparatus or the insertion of elements of the apparatus into the cassette. Above the magnetic tape cassette a certain clearance is required for the swung-open cassette cover. However, this clearance may be comparatively small and need not be greater than the height dimension of the magnetic tape cassette, but may even be smaller.

In most cassette equipment, the magnetic tape cassette is not placed directly onto the deck by hand, but is slid into a movable cassette holder, after which the cassette holder is moved towards the deck. The magnetic tape cassette in accordance with the invention is particularly suitable for such applications, because the movement of the magnetic tape cassette towards the deck allows provisions to be made on the deck for opening the cassette cover during the movement of the cassette holder. The cassette cover which is thus opened during the movement of the cassette holder does not impede insertion into the magnetic tape cassette of elements such as capstans, pressure rollers, magnetic tape retaining elements or elements for withdrawing the magnetic tape from the cassette.

Single Pivot

In a simple embodiment of the invention pivotal bearing means are disposed midway between the first and the second main wall and the cassette cover is pivotable in its first and its second pivoting directions about a single pivoting axis midway between the two main walls. This embodiment reduces the likelihood of the cassette cover touching the portion of the magnetic tape which is tensioned along the front of the magnetic tape cassette, during the pivotal movement of the cover, if the pivoting axis is situated somewhat to the rear of the magnetic tape cassette.

Double Pivot

In a preferred embodiment of the invention the pivotal bearing means comprise a first pivotal bearing means disposed nearer the side of the first main wall for pivoting the cassette cover in its first pivoting direction about a first pivoting axis which is also nearer the side of the first main wall, as well as a second pivotal bearing means disposed nearer the side o

f the second main wall for pivoting the cassette cover in its second pivoting direction about a second pivoting axis which is likewise nearer the side of the second main wall. This embodiment has the advantage that the distance between the stretched portion of the magnetic tape, which extends along the front of the magnetic tape cassette, and the inner side of the cassette cover, which faces the magnetic tape, can be reduced and that moreover the pivoting axes can be situated nearer the front of the cassette housing, without the risk of the magnetic tape being damaged. Thus smaller cassette dimensions are obtained. A further advantage of this embodiment is that the cassette cover can be pivoted into a position in which the front side of the cassette cover extends parallel to the main walls of the cassette housing without occupying much room in the apparatus, so that optimum accessibility of elements of the cassette apparatus to the magnetic tape is obtained.

f the second main wall for pivoting the cassette cover in its second pivoting direction about a second pivoting axis which is likewise nearer the side of the second main wall. This embodiment has the advantage that the distance between the stretched portion of the magnetic tape, which extends along the front of the magnetic tape cassette, and the inner side of the cassette cover, which faces the magnetic tape, can be reduced and that moreover the pivoting axes can be situated nearer the front of the cassette housing, without the risk of the magnetic tape being damaged. Thus smaller cassette dimensions are obtained. A further advantage of this embodiment is that the cassette cover can be pivoted into a position in which the front side of the cassette cover extends parallel to the main walls of the cassette housing without occupying much room in the apparatus, so that optimum accessibility of elements of the cassette apparatus to the magnetic tape is obtained.Bearing constructions which enable a component to be pivoted into two different pivoting directions about two different parallel pivoting axes are known. Examples of these are the known hinge construction for swing doors, while there are also constructions comprising crosswise arranged straps.

A simple bearing construction which is suitable for a magnetic tape cassette is obtained with an embodiment of the invention in which the first pivotal bearing means include fist bearing journals as well as parts of the magnetic tape cassette which define first bearing recesses which receive the first bearing journals, and the second pivotal bearing means include second bearing journals as well as parts of the magnetic tape cassette which define second bearing recesses which receive the second bearing journals. These bearing recesses each have an opening at their circumference to allow movement of the first bearing journals out of the first bearing recesses during pivotal movement of the cassette cover about the second pivoting axis, and to allow movement of the second bearing journals out of the second bearing recesses during pivotal movement of the cassette cover about the first pivoting axis.

In this embodiment it is necessary to prevent the cassette cover in its closed or swung open positions, or during its pivotal movement, from becoming detached from the cassette housing by movement of the bearing journals out of the bearing recesses. In a further preferred embodiment parts of the magnetic tape cassette define arcuate first guide slots which each terminate in the respective openings in the circumference of the first bearing recesses, for guiding the first bearing journals with play during the pivotal movement of the cassette cover in its second pivoting direction; and parts of the magnetic tape cassette define arcuate second guide slots which each terminate in the respective openings in the circumference of the second bearing recesses, for guiding the second bearing journals with play during the pivotal movement of the cassette cover in its first pivoting direction. These parts of the magnetic tape cassette consist of parts of the side walls of the cassette housing if the bearing journals are disposed on the pivoting arms of the cassette cover, or consist of parts of the pivoting arms if the bearing journals are disposed on the side walls of the cassette housing.

The two guide slots intersect each other midway between the two main walls of the cassette housing. At the location of the intersection there is a possibility that a bearing journal does not move in the corresponding guide slot, so that the cassette cover could assume a wrong position. It is therefore advantageous to use an embodiment in which the bearing recesses have an at least partly circular cross-section with a diameter equal to the maximum transverse dimension of the associated bearing journal plus the play; the bearing journals have an elongate shape with a width dimension which is smaller than the length dimension; and the arcuate slots have a width dimension which is adapted to the width dimension of the associated bearing journal and is smaller than the diameter of the associated bearing recess. This embodiment prevents movements of the cassette cover other than in the first or the second pivoting direction in every position of the cassette cover, by cooperation of the bearing journals and parts of the cassette housing.

If the bearing journals are disposed on the pivoting arms and the guide slots are disposed in the side walls of the cassette housing, in another preferred embodiment providing a simple mounting of the cassette cover, each side wall of the cassette housing has mounting slots which extend in the direction of the bearing recesses and which intersect the guide slots at intersections, for mounting the bearing journals in the bearing recesses. The mounting slots each have an open entry side to allow unimpeded entry of the bearing journal into the mounting slot, and furthermore have a bottom with a profile which extends from a level at which there is play between the cassette cover and the cassette housing to a level at which the cassette cover is slightly bent by an interference fit between the bearing journals and the bottom of the mounting slots. Thus, when the cassette cover is being mounted, the cassette cover is slightly bent until the bearing journals engage with the bearing recesses, after which the bearing journals snap into the bearing recesses as a result of the resilient action of the cassette cover itself.

In order to obtain well-defined open positions of the cassette cover in a magnetic tape cassette of the types described above having first and second pivoting axes, according to another preferred embodiment of the invention in which the bearing journals are disposed on the pivoting arms of the cassette cover, the cassette housing is provided with stops which are adapted to cooperate with the second bearing journals so as to limit the pivotal movement of the cassette cover in its first pivoting direction, and with stops which are adapted to cooperate with the first bearing journals so as to limit the pivotal movement of the cassette cover in its second pivoting direction. In the embodiment in which guide slots for the bearing journals are formed in the side walls of the magnetic tape cassette, each of the guide slots at its end which is remote from the corresponding bearing recess may terminate at a portion of the side wall of the cassette housing, which portion functions as one of the stops which is adapted to cooperate with the bearing journals so as to limit the pivotal movements of the cassette cover.

Slide Plates

The invention is suitable both for audio and for video cassettes, both when they are not provided with cut-outs in the main walls which are open towards the front of the cassette housing and when such cut-outs are provided. However, it is a further object of the invention to provide a magnetic tape cassette having maximum fields of application. For such an objective it is necessary to form large cut-outs in the main walls of the cassette housing to permit the passage of elements of cassette apparatus of different types. In the case in which large cut-outs in the main walls of the cassette housing extend to the front, there is an increased risk of the magnetic tape being damaged and of dust and dirt penetrating into the interior of the cassette.

An embodiment of the invention, which satisfies this object, includes a first and a second slide plate respectively disposed near the first and second main walls, each slide plate being movable between a retracted position nearer the rear of the cassette housing and a closing position nearer the front of the cassette housing. Each slide plate leaves the respective openings in the corresponding main wall clear in its retracted position, and closes these openings at least partly and preferably completely in the closing position. Thus it is possible to provide magnetic tape cassettes which, once they have been removed from the cassette apparatus, are almost completely closed, except of course for the openings in the main walls for the passage of drive spindles for the magnetic tape reels; but which, once they have been placed on a cassette apparatus, first of all have a fully open front, and secondly also provide satisfactory access behind (to the back side of) the magnetic tape to allow passage of elements of a cassette apparatus through the cut-outs in the main walls.

An embodiment is preferred in which the two slide plates are part of a single slide member which is bodily movable between the retracted position and the closing position, which member also includes two side walls which extend along the side walls of the cassette housing and which interconnect the slide plates. The slide member may then be formed as a unitary component which is integrally manufactured from a plastic. These embodiments have the advantage that easy guidance and journalling of the slide plates on the cassette housing is assured.

Alternatively, according to another preferred embodiment, the slide member comprises two identical parts which are integrally manufactured from a plastic, which parts are provided with snap-connection means and are interconnected thereby through a snapped connection. As the two parts of the slide member are identical only one tool is required for manufacturing the slide member. The advantage of this embodiment mainly resides in the simplified mounting of the slide member. By using the snapped connection, the member can readily be mounted on the cassette housing after the magnetic tape reels and the cassette cover have been mounted in and on the cassette housing respectively. If the two pivoting arms of the cassette cover are located on the outside of the cassette housing, in a still further preferred embodiment the side walls of the slide member cover the pivoting arms in the closed position of the cassette cover. Thus, the pivoting arms are well protected when the magnetic tape cassette is removed from a cassette apparatus, so that the comparatively vulnerable bearing means of the cassette cover are protected against mechanical dam

aging. Moreover, a magnetic tape cassette is thus obtained with a clean-cut and smooth appearance, because the bearing constructions are covered by the side walls of the slide member.

aging. Moreover, a magnetic tape cassette is thus obtained with a clean-cut and smooth appearance, because the bearing constructions are covered by the side walls of the slide member.Spring Restraints

For specific uses of the magnetic tape cassette in accordance with the invention it may be of importance that, once a cassette cover is open, it does not swing back to its closed position under the influence of gravity. An embodiment of the invention which is of interest in this respect includes resilient means which load the cassette cover relative to other parts of the magnetic tape cassette, the cassette cover being in a stable balanced position under the influence of the resilient load in its first and in its second open position for any orientation of the cassette relative to the direction of the force of gravity. The resilient means may for example act on the cassette cover and on the slide member and urge these components towards each other. Leaf spring constructions are also possible which cooperate with non-round bearing journals of the cassette cover. However, it is not always desirable to subject the cassette cover to a resilient load, because the bistable positions which the cassette cover can assume under the influence of the resilient menas require that the cassette apparatus include means for closing the cassette cover against the resilient load.

Comparatively simple means on the cassette apparatus are sufficient for moving the slide plates. Since the slide plates slide over the main walls of the cassette housing they are easily opened during the operation of inserting the magnetic tape cassette into a cassette holder. Preferably, resilient means are provided which act both on the cassette housing and on the slide plates so as to urge the slide plates towards their closing positions. With the aid of these resilient means the slide plates are always automatically moved towards their closed positions when the magnetic tape cassette is removed from the cassette apparatus. Moreover, the resilient means enable automatic ejection or at least partial ejection of a magnetic tape cassette from a cassette holder.

Accommodating the resilient means in the magnetic tape cassette may be a problem in view of the limited space which is available. When a slide member which is bodily movable is used, an embodiment is therefore of interest which makes optimum use of the space available in a magnetic tape cassette. In this embodiment the first and the second slide plates of the slide member are interconnected halfway between its two side walls and behind the magnetic tape by means of a connecting member, and the resilient means for loading the slide member towards the closed position comprise a pressure spring between the connecting member and the cassette housing. Thus, in the cassette housing a space exists halfway between its side walls and between the two circular reels, which can readily accommodate a helically wound pressure spring, so that the available and generally unused room can be utilized. A further advantage of this embodiment is that owing to the connection between the two slide plates at a location between the two side walls of the slide member the slide member is given a higher rigidity. If the slide member consists of a unitary component which is integrally manufactured from a plastic, it is advantageous to manufacture the slide member and the connecting member together as a single integrally manufactured component. As the connecting member is located behind the magnetic tape, mounting of such a slide member may be difficult. In an embodiment which overcomes this problem the unit comprising the slide member and the connecting member is made of two identical parts which are integrally manufactured from a plastic and provided with snap-connection means, the parts being interconnected by a snapped connection. After the magnetic tape reels have been mounted in the cassette housing and, as the case may be, also after mounting the cassette cover, the slide member can be fitted onto the cassette housing by moving the two parts of the slide member towards each other in a direction perpendicular to the main walls of the cassette housing and interconnecting them by means of a snapped connection. Subsequently, the pressure spring can be mounted between the cassette housing and the slide member.

Cover/Slide Movement

When a bodily movable slide member is used, in yet another preferred embodiment the slide member and the cassette cover are provided with cooperating parts for pivoting the cassette cover towards its closed position, no matter which of its two open positions the cassette cover occupies. The advantage of this embodiment is that the movement of the slide member to its closing position and the pivotal movement of the cassette over from an open position to its closed position can proceed in a single operation, when the slide member is moved towards its closing position. Furthermore, it is advantageous if the slide member and the cassette cover are provided with cooperating latching means which prevent the cassette cover from moving to the open position when the slide member is in the closing position. Thus, the cassette cover will always stay closed as long as the slide member is in its closing position.

For moving the slide member and subsequently opening the cassette cover when the magnetic tape cassette is placed on the cassette apparatus, in yet another preferred embodiment the edge of each of the side walls of the slide member remote from the rear of the cassette housing is arranged to be clear of the cassette cover, at least at locations which are disposed near the main walls. This edge may then be used as a stop means for moving the slide member to its retracted position when the magnetic tape cassette is placed in a cassette holder of the cassette apparatus. For opening the cassette cover after the cassette has been inserted and for moving the slide member in the cassette holder, in a different preferred embodiment the corresponding edge of each of the side walls of the slide member which is remote from the rear of the cassette housing has a recess formed at a location midway between the main walls of the cassette housing. The cassette cover is then provided with lateral projections which engage the recesses when the cassette cover is closed. These projections may be used to open the cassette cover by engaging elements on a cassette apparatus during movement of the cassette holder to an operating position.

In a magnetic tape cassette in accordance with the invention each of the slide plates will have a length dimension which is roughly equal to the distance between the side walls of the cassette housing; and transverse thereto, a width dimension which is substantially smaller. This occurs because the width dimension must be limited so that when the slide plate is in its retracted position the plate does not interfere with the drive means for the magnetic tape reels. The comparatively great length/width ratio of the slide plates is apt to cause the plates to jam if a slide plate or a slide member does not perform a purely translational movement between its closing position and its retracted position, but rather twists slightly about an axis parallel to the axes of rotation of the magnetic-tape reels. Since jamming of the slide plates or the bodily movable slide member is obviously undesirable, in another preferred embodiment of the invention each of the side walls of the cassette housing, at the location of the side walls of the slide member when this member is in its retracted position, is provided with a curved profile with a radius of curvature which is substantially equal to the distance between the two side walls of the cassette housing. This profile enables the slide member to twist a little relative to the cassette housing, such that one side wall of the slide member is nearer the rear of the cassette housing than the other side wall of the slide member, without the slide member becoming jammed on the cassette housing.

In a different embodiment which is adapted to eliminate jamming effects, each of the side walls of the slide member comprises a portion which protrudes towards the rear of the cassette housing, so arranged that in the closing position of the slide member each side wall of the slide member extends beyond the location occupied by those sides of the slide plates of the slide member facing the rear of the cassette housing when the slide member is in its retracted position. That lo

cation, as previously stated, is dictated by the fact that the slide plates should not interfere with the drive means for the magnetic tape reels. However, the side walls of the slide member may extend further towards the rear of the cassette housing, so that a favorable ratio is obtained between the length of the slide member and its width at the location of the side walls. A further advantage is the improved appearance obtained by the use of the protruding portions, when the slide member is in the closed position; that is, the outward appearance viewed at a main wall is not spoiled by a stepwise change required because of the thickness of the slide member.

cation, as previously stated, is dictated by the fact that the slide plates should not interfere with the drive means for the magnetic tape reels. However, the side walls of the slide member may extend further towards the rear of the cassette housing, so that a favorable ratio is obtained between the length of the slide member and its width at the location of the side walls. A further advantage is the improved appearance obtained by the use of the protruding portions, when the slide member is in the closed position; that is, the outward appearance viewed at a main wall is not spoiled by a stepwise change required because of the thickness of the slide member.In many cases, especially if the slide member is loaded towards its closing position by resilient means, it is advantageous if the slide member and the housing are provided with cooperating stop means to prevent a slide member, once it has been mounted, from sliding off the cassette housing when the cassette cover has not yet been mounted or has been removed. This embodiment provides greater ease of handling the magnetic tape cassette during assembly. In addition, if the cassette includes resilient means for loading the slide member towards the closing position, a further advantage is obtained from this embodiment if, while the slide member is in the closing position, the stop means engage the slide member and transmit at least the greater part of the resilient load imposed by the resilient means to the cassette housing. When this embodiment is used the cassette cover, and thus the bearing means for the pivotal movements of the cassette cover, are not loaded by the resilient means.

BRIEF DESCRIPTION OF THE DRAWING

The invention will now be described in more detail with reference to the drawing, in which:

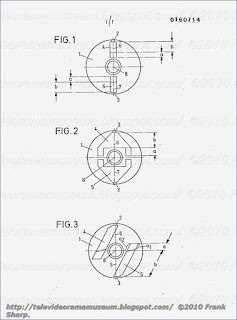

FIG. 1 is a view at a first main surface of a magnetic tape cassette having a cassette cover which is pivotable about a single axis,

FIG. 2 is a side view at the cassette cover of the magnetic tape cassette in accordance with FIG. 1,

FIG. 3 is a view at a second main surface of the cassette of FIG. 1.

FIG. 4 is a side view of the magnetic tape cassette in accordance with the preceding Figures,

FIG. 5 is a detail of FIG. 4, showing the cassette cover swung open in a first pivoting direction, and a dashed line showing the cassette cover in a second open position in a second pivoting direction,

FIG. 6 is a view similar to FIG. 1, but of a magnetic tape cassette having a cassette cover pivotable about two pivoting axis and a slide member for closing the openings in the main walls,

FIG. 7 is a front view of the magnetic tape cassette of FIG. 6,

FIG. 8 is a view in accordance with FIG. 6, but now at a different main surface of the magnetic tape cassette,

FIG. 9 is a perspective view of the cassette in accordance with FIGS. 6 to 8, the slide member being in its closing position and the cassette cover being in its closed position,

FIG. 10 is similar to FIG. 9, but with the slide member in its retracted position and the cassette cover opened in a first pivoting direction,

FIG. 11 is similar to FIG. 10, but with the cassette cover opened in a second pivoting direction,

FIG. 12 is a partial exploded view of a magnetic tape cassette in accordance with FIGS. 6 to 11,

FIG. 13 shows a detail of one of the side walls of the cassette in accordance with FIGS. 6 to 12, the position of the bearing journals being shown relative to the bearing recesses and the guide slots when the cassette cover is closed,

FIG. 14, shows the same detail as FIG. 13, but with the cassette cover opened in a first pivoting direction,

FIG. 15 is a sectional view in accordance with the arrows XV--XV in FIG. 14,

FIG. 16 is a cross-section across the center of the slide member and in accordance with the arrows XVI--XVI in FIG. 12,

FIG. 17 is a partial cross-section in accordance with the arrows XVII--XVII in FIG. 16,

FIGS. 18, 19 and 20 are views of a connecting member for interconnecting the slide plates of the slide member in the magnetic tape cassette in accordance with FIGS. 6 to 12,

FIG. 21 shows an integrally manufactured plastic version of a slide member for a magnetic tape cassette in accordance with FIGS. 6 to 12,

FIG. 22 shows a slide member consisting of two plastic components which have been snapped together for the magnetic tape cassette in accordance with FIGS. 6 to 12,

FIG. 23 shows a detail of one of the snap connections for interconnecting the parts of the slide member in accordance with FIG. 22,

FIG. 24 and FIG. 25 illustrate the principle of an embodiment in which a slide member and a cassette cover are loaded relative to each other by means of a tension spring, FIG. 24 representing the situation with the cassette cover closed and FIG. 25 the situation with the cassette cover open,

FIG. 26 is similar to FIG. 8, but with the slide member in a twisted position,

FIG. 27 is a similar view as in FIG. 9 of a modified embodiment, with a slide member which has portions protruding towards the rear of the cassette housing,

FIG. 28 is a view at a main wall of the magnetic tape cassette in accordance with FIG. 27,

FIG. 29 schematically shows a part of a cassette apparatus with a hinged cassette holder containing a cassette in accordance with the invention, the slide member being moved into its more retracted position during insertion of the cassette, and

FIG. 30 is similar to FIG. 29, but with the cassette holder in its operating position and the cassette cover being opened by means provided on the deck of the cassette apparatus.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

Single Pivot

The magnetic tape cassette 1 in accordance with FIGS. 1 to 3 is adapted to cooperate with a cassette apparatus in a first position, as is shown in FIG. 1, and in a reversed second position, as shown in FIG. 3. As is customary with such so-called reversible cassettes, the two main walls are provided with designations "1" and "2" respectively, for the user. The magnetic tape cassette has a first and a second adjacently disposed reel hub 2 and 3 respectively, which are rotatable about parallel spaced axes of rotation, not shown. These hubs each have a central opening 4 and 5 respectively for engagement by a reel hub drive spindle which belongs to the cassette apparatus. Around the central openings 4 and 5 a number of openings 6 and 7 respectively are formed for a reel hub carrier pin of the cassette apparatus. The cassette 1 housing includes a first main wall 8 and, parallel thereto, a main wall 9. The main wall 8 has a first opening 10 coaxial with the first reel hub 2 to allow passage of a reel drive spindle, and a similar second opening 11 for the second reel hub 3. The second main wall 9 has corresponding first and second openings 12 and 13 respectively. The main walls 8 and 9 are interconnected by side walls 14 and 15 at their short sides, and by a rear wall 16. The reel hubs 2 and 3 have reel flanges 17 and 18 respectively. A length of magnetic tape 19 is connected to the reel hubs 2 and 3 at its two ends, so as to enable it to be wound back and forth between the first reel 2 and the second reel 3. Near a front opening 20, opposite the rear 16 of the cassette, a portion 21 of the tape 19 is stretched in a position where it can be engaged by parts of a cassette apparatus. To keep the stretched tape position 21 taut along the front of the cassette housing two guide rollers 22 and 23 are located between the two main walls 8 and 9 of the cassette housing. In the main wall 8 three cut-outs 24, 25 and 26 are formed, which are open towards and extend to the front opening 20 of the cassette housing, for the passage of components of a cassette apparatus behind the stretched tape portion 21 and to allow withdrawing the magnetic tape from the cassette housing. The main wall 9 has a corresponding cut-outs 27, 28 and 29 which also extend to the front opening 20.

The magnetic tape cassette 1 in accordance with FIGS. 1 to 3 is adapted to cooperate with a cassette apparatus in a first position, as is shown in FIG. 1, and in a reversed second position, as shown in FIG. 3. As is customary with such so-called reversible cassettes, the two main walls are provided with designations "1" and "2" respectively, for the user. The magnetic tape cassette has a first and a second adjacently disposed reel hub 2 and 3 respectively, which are rotatable about parallel spaced axes of rotation, not shown. These hubs each have a central opening 4 and 5 respectively for engagement by a reel hub drive spindle which belongs to the cassette apparatus. Around the central openings 4 and 5 a number of openings 6 and 7 respectively are formed for a reel hub carrier pin of the cassette apparatus. The cassette 1 housing includes a first main wall 8 and, parallel thereto, a main wall 9. The main wall 8 has a first opening 10 coaxial with the first reel hub 2 to allow passage of a reel drive spindle, and a similar second opening 11 for the second reel hub 3. The second main wall 9 has corresponding first and second openings 12 and 13 respectively. The main walls 8 and 9 are interconnected by side walls 14 and 15 at their short sides, and by a rear wall 16. The reel hubs 2 and 3 have reel flanges 17 and 18 respectively. A length of magnetic tape 19 is connected to the reel hubs 2 and 3 at its two ends, so as to enable it to be wound back and forth between the first reel 2 and the second reel 3. Near a front opening 20, opposite the rear 16 of the cassette, a portion 21 of the tape 19 is stretched in a position where it can be engaged by parts of a cassette apparatus. To keep the stretched tape position 21 taut along the front of the cassette housing two guide rollers 22 and 23 are located between the two main walls 8 and 9 of the cassette housing. In the main wall 8 three cut-outs 24, 25 and 26 are formed, which are open towards and extend to the front opening 20 of the cassette housing, for the passage of components of a cassette apparatus behind the stretched tape portion 21 and to allow withdrawing the magnetic tape from the cassette housing. The main wall 9 has a corresponding cut-outs 27, 28 and 29 which also extend to the front opening 20.A cassette cover 30 is connected to the cassette housing and is pivotable relative thereto about a pivoting axis 31 parallel to the main walls, between a closed position, shown in FIGS. 1 to 4, and an open position which is obtained by a pivotal movement in a pivoting direction towards a main surface of the cassette housing. The cassette cover covers substantially the entire front opening 20 of the cassette housing.

On both sides the cassette cover is provided with pivoting arms 32 and 33 having free ends 34 and 35 respectively, the arms extending along the respective side walls 14 and 15 of the cassette housing, toward the housing rear when in the closed position. The pivoting arms have free ends 34 and 35 respectively which face the rear 16 of the cassette housing in the closed position. The side walls 14 and 15 of the cassette housing and the pivoting arms 32 and 33 of the cassette cover 30 are provided with pivotal bearing means which cooperate with each other near the free ends 34 and 35 of the pivoting arms 32 and 33. As is shown in FIG. 5 the cassette cover 30 is pivotable from its closed position into two different opened positions. Solid lines in FIG. 5 represent a first open position of the cassette cover 30, which is reached by pivoting the cassette cover in a first pivoting direction indicated by an arrow 36 towards the first main wall 8 of the cassette housing. Dashed lines represent a second open position of the cassette cover reached by pivoting the cassette cover in a second pivoting direction in accordance with an arrow 37 towards the second main wall 9. The main wall 8 has slots 38 and 39 which are open towards the front 20 of the cassette housing for the passage of the pivoting arms 32 and 33 when the cassette cover 30 is pivoted in its first pivoting direction 36. The main wall 9 has corresponding slots 40 and 41 for pivoting in the second pivoting direction 37. The bearing means for the pivotal bearing of the cassette cover comprise two bearing journals 42 and 43 near the free ends 34 and 35 of the pivoting arms 32 and 33 and corresponding recesses in the side walls 14 and 15 of the cassette housing. An example of such a recess is the recess 44 in FIGS. 4 and 5.

The bearing journals 42 and 43 have a square cross-section and the recess 44 as well as the corresponding recess, not shown, in the side wall 15 of the cassette housing has a semicircular cross-section. In the side walls at the location of the bearing journals 42 and 43 leaf springs 45 provide a simple spring restraint for loading the bearing journals towards the rear 16 of the cassette housing. Because of the resilience of the leaf springs loading the square cross-section of the bearing journals of the cassette cover, the cassette cover will be held in a stable balanced position, both in its closed position and in its two open positions for any orientation of the magnetic tape cassette relative to the direction of the force or gravity.

Double Pivots

FIGS. 6 to 20

relate to a different embodiment of the invention. The magnetic tape cassette 47 is largely identical to the magnetic tape cassette 1 of FIGS. 1 to 5. The cassette includes reel hubs 48 and 49 with central openings 50 and 51 and additional openings 52 and 53 arranged around the central openings. The cassette housing comprises a first main wall 54 and a second main wall 55 with first openings 56 and 57 respectively, and with second openings 58 and 59 respectively, for the reel hubs 48 and 49. The main walls 54 and 55 are interconnected by side walls 60 and 61 and a rear wall 62. Opposite the rear wall there is located a front opening 63, see FIGS. 10 to 12. The cassette housing accommodates a magnetic tape 64 with a stretched tape portion 65 near the front 63.